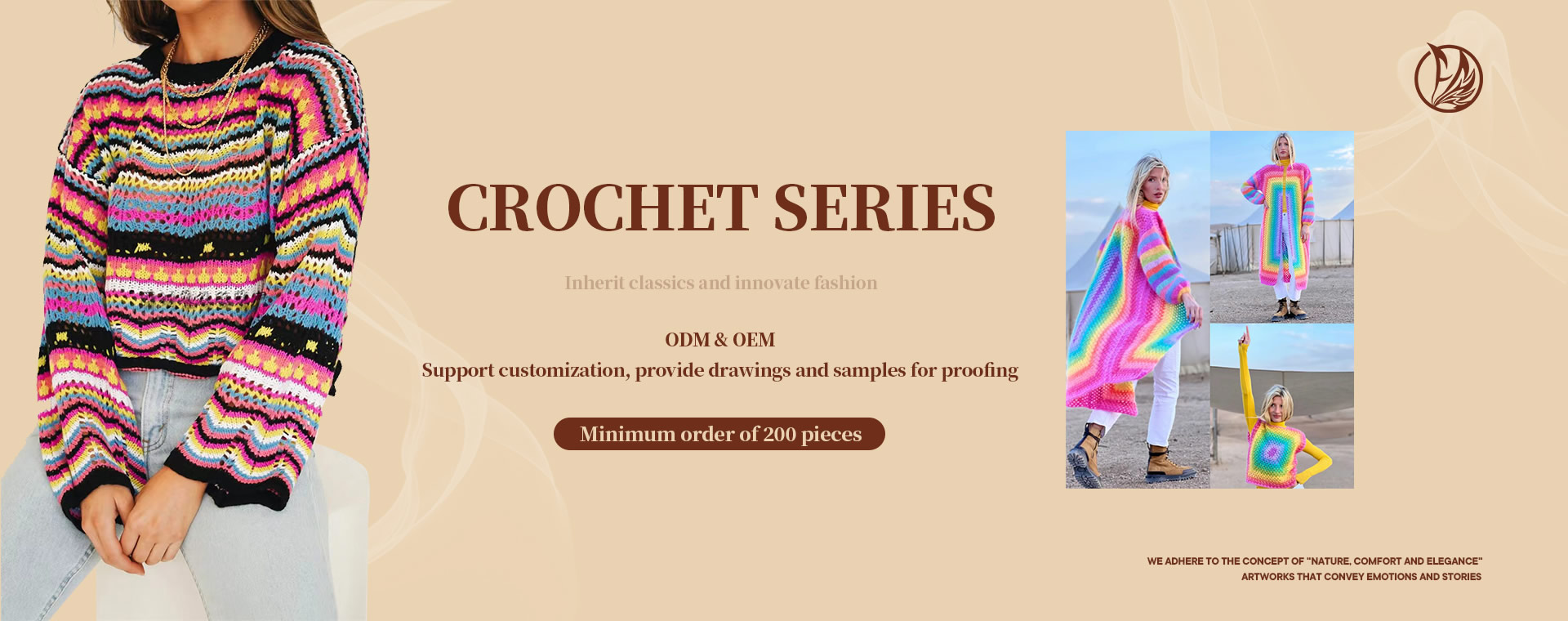

Detailed process of sweater weaving technology

Date:2022-11-05

The weaving process of sweaters mainly includes the following steps:

Yarn preparation: Yarn is the most basic raw material for knitting sweaters, including various types such as cotton yarn, wool, silk thread, and hemp thread. Different types of yarns are suitable for different weaving projects, such as sweater weaving suitable for winter.

Needle selection: Knitting sweaters also requires the use of needles, which include straight needles, crochet needles, double headed needles, etc. Choosing the appropriate needle can make the weaving process smoother.

Starting and basic needlework: Before knitting a sweater, it is necessary to learn several basic needlework techniques, such as starting, elastic edges (weaving sleeves, neckline, and hem), adding needles, and closing edges. When starting a stitch, it is necessary to calculate the required number of stitches based on the style and size of the sweater.

Knitting: A sweater consists of a large body, back, two sleeves, and other parts that need to be woven on a machine. Weaving is generally divided into manual weaving and machine weaving (such as computerized flat knitting).

Cutting bed: Cut the fabric into the desired shape according to the paper pattern. Most machine woven fabrics require cutting, while handmade fabrics require less cutting.

Picking and washing: Picking and washing are areas that cannot be sewn by hand needles combined with machines, while washing is to remove stains from the sweater and control the feel and softness of the sweater.

Hot stamping and car marking: Hot stamping is the process of shaping and fixing the size of a sweater, while car marking is the process of sewing the customer's requested marks (such as the main mark, washing mark, size, etc.) onto the sweater.

Inspect and repair sweaters: Conduct quality checks on sweaters, repair defects in weaving, and damage caused by yarn removal from the sewing disc.

Packaging: Folding, packaging, and boxing of sweaters.

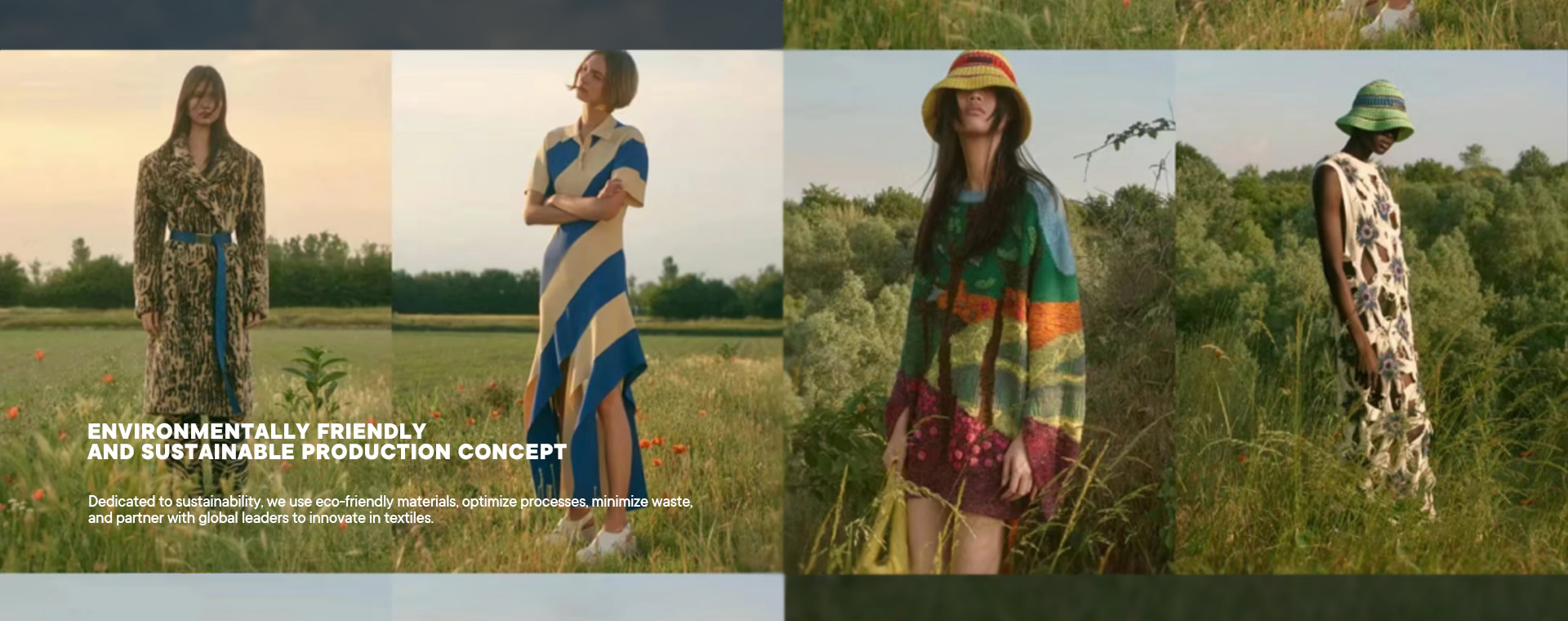

The weaving process of a sweater may also include some other processing steps, such as dyeing, printing, hair planting, singeing, embroidery, and beading, to increase the aesthetics and practicality of the sweater. These processes will be selected and combined based on the style of the sweater and customer needs.

Previous:The influence of sweater weaving technology on the warmth re

Next:No time